As we know, Ferrite chip inductors and Ferrite beads are very similar products from the appearance, and today we will talk about the difference between them.

Ferrite Chip Inductor

Ferrite Beads

What is Ferrite chip inductor?

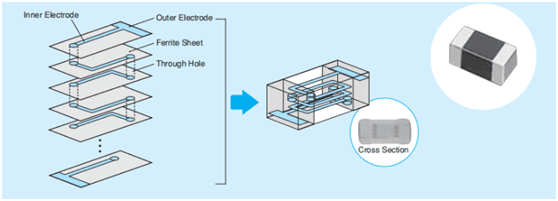

Ferrite chip inductor is a kind of inductor which is formed by stacking several ferrite Multilayer together, the main factor of inductors are inductance, DCR and current, the unit of inductance is uH or mH.

Ferrite chip inductor internal structure

1. Classification of ferrite chip inductors:

According to different application requirements and structural characteristics, ferrite chip inductors can be classified by their shape, material type, or operating frequency. Among them, the common classification methods are:

By shape: including cap-type ferrite inductors, cylindrical ferrite inductors, plate-type ferrite inductors, etc..

By material type: including MnZn ferrite inductors and NiZn ferrite inductors;

By operating frequency, ferrite chip inductors can be divided into low-frequency types and high-frequency types.

2. Application of ferrite chip inductors:

Ferrite chip inductors are widely used in various high-frequency circuits, such as radios, televisions, computers and other equipment, and also play an irreplaceable role in power supply filtering, matching networks, tuning circuits, interference suppression, etc. In addition, ferrite chip inductors are also widely used in wireless communications, military radars, seismic exploration and other fields.

What is ferrite beads?

Ferrite beads are also called Ferrite bead filter, and the main material is ferrite. It is a ferrimagnetic material with a cubic crystal structure and has high magnetic permeability and high temperature properties. The main of Ferrite beads is impedance(impedance values tested at 100MHz), the unit of impedance is ohm(Ω).

(★ For more information on ferrite beads, see this article: • How Do Ferrite Beads Work? | We Understand From The Selection And Application Of Ferrite Beads)

Ferrite Beads internal structure

1. Material of ferrite beads:

The material of ferrite beads is mainly ferrite. Ferrite is a metal oxide with high magnetic permeability, composed of iron, manganese, zinc and other elements. Among them, manganese ferrite and zinc ferrite are the most commonly used magnetic bead materials. Manganese ferrite has a high magnetic permeability and can generate inductive reactance at lower frequencies, while zinc ferrite has a low magnetic permeability and is mainly used at high frequencies.

2. Application of ferrite beads:

Ferrite beads are widely used in various electronic devices, such as power lines, signal lines, network card interfaces, etc. In these devices, ferrite beads can effectively absorb high-frequency noise and prevent interference signals from affecting the normal operation of the equipment. At the same time, ferrite beads can also be used to suppress the noise generated by switching power supplies.

In the selection of magnetic components, the choice of ferrite beads or ferrite inductors

For EMI (electromagnetic interference) filter circuits, magnetic beads with good magnetic properties and anti-electromagnetic interference capabilities should be selected.

For DC filter circuits, regulated power supply output filter circuits, DC/DC converter input and output inductors, etc., ferrite chip inductors should be selected because of their good linearity, small distortion, low magnetic leakage, and good temperature stability.

In what specific cases is it not recommended to replace a ferrite bead with an inductor?

When considering the replacement of ferrite beads with inductors, it’s essential to understand that these components, while similar in some respects, serve different purposes and are suited to distinct applications. Here are key scenarios where replacing ferrite beads with inductors is not recommended:

1. High-Frequency Noise Suppression

Ferrite beads are specifically designed to suppress high-frequency noise due to their frequency-dependent impedance characteristics. They effectively filter out unwanted high-frequency signals without significant impact on the desired low-frequency signals. Inductors, on the other hand, do not have this sharply reactive nature and may not be as efficient at high-frequency noise suppression, which can lead to degraded performance in circuits requiring precise noise filtering.

2. Power Delivery Systems

In power delivery systems, ferrite beads are often preferred because they can handle substantial amounts of current while offering minimal DC resistance. This characteristic helps in maintaining power integrity. Inductors generally exhibit higher resistance and may introduce unnecessary power loss or voltage drops, making them unsuitable for such applications.

3. Size Constraints

Ferrite beads are compact and effective at filtering EMI (Electromagnetic Interference) in limited space. Inductors, however, typically occupy more board space for a similar inductance value, especially when designed to handle equivalent currents. In scenarios where PCB real estate is at a premium, replacing ferrite beads with inductors may not be practical.

4. Broadband Filtering

Ferrite beads provide efficient broadband filtering, thanks to their inherent frequency characteristics. Inductors are often suitable for narrow bandpass or low-pass filtering but lack the broadband capability necessary for addressing a wide range of noise frequencies. If broadband EMI suppression is critical, sticking with ferrite beads is advisable.

Summary Points:

- High-frequency Noise: Ferrite beads excel, whereas inductors may fail.

- Power Delivery: Higher efficiency with ferrite beads due to minimal resistance.

- Size: Ferrite beads offer a more compact solution.

- Broadband Filtering: Ferrite beads are better suited for a wide frequency range noise suppression.

In conclusion, while inductors and ferrite beads might seem interchangeable at a glance, these distinct scenarios underscore why substituting one for the other is not always advisable. Carefully assess the specific requirements of your application to make an informed decision.

Zxcompo products include multilayer power inductors, wound surface mount inductors, and molded surface mount inductors for power and signal lines. A full range of passive electronic and magnetic components, including inductors, capacitors, resistors, transformers, and filters, is available. Our products are widely used in automotive, telecommunications, consumer electronics, and other fields. Each product is designed to achieve performance and maximize signal and power efficiency while saving space.

Other advantages include:

Fully automated manufacturing

High-reliability AEC-Q200

ISO 9001 quality standards

RoHS compliant

REACH compliant

Why choose Zxcompo?

Our company has more than 1,000 types of inductors and 15 years of experience in this field. It is a product that produces extremely low resistance over a wide frequency range. Zxcompo is widely recognized by a global technical team for designing, manufacturing, and providing high-quality, high-performance signal integrity and noise filtering solutions.

Zxcompo brand inductors, also known as coils or reactors, are passive electronic components that resist changes in the current flowing through them. Core material, winding type and geometry play a critical role in the performance of power inductors. Shipping worldwide. Simply contact us for samples: sales@ZXcompo.com.