I. Introduction

Inductor coils are integral components in many electrical applications. Their performance can significantly affect the efficiency and effectiveness of the devices they are part of. One of the key factors that determine the performance of an inductor coil is the material from which it is made.

II. Understanding Inductor Coils

An inductor coil is an electrical component that stores energy in a magnetic field when electric current flows through it. The design and construction of the coil, including the type of material used, can greatly affect its performance. For instance, the coil’s inductance, which is its ability to resist changes in electric current, can be influenced by the material’s properties.

III. The Impact of Different Materials

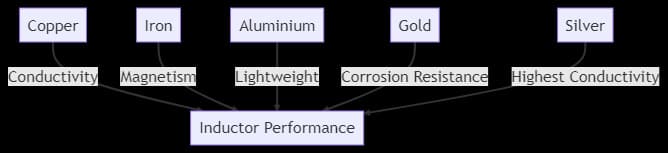

There are various materials that can be used in the construction of inductor coils. Each material has unique properties that can affect the performance of the coil. For instance, core materials such as ferrite, iron, and laminated cores each have different magnetic properties. Wire materials like copper, aluminum, and silver have varying levels of electrical conductivity. Even the insulation materials, which can range from enamel to polyester to polyimide, can impact the coil’s performance. Understanding these materials and their properties can help in optimizing the efficiency and performance of the coil.

IV. Factors to Consider in Material Selection

When selecting materials for an inductor coil, several factors need to be considered. These include the material’s electrical conductivity and resistance, its magnetic permeability and saturation point, its thermal properties and ability to dissipate heat, and its mechanical strength and durability. Cost is also a significant consideration, as the material cost can significantly affect the overall cost of the coil.

V. Customizable Inductor Coils for Specific Applications

Inductor coils can be customized to meet the unique requirements of different applications. By tailoring the coil materials, it is possible to optimize the coil’s performance for specific industries, such as automotive, telecommunications, renewable energy, and medical devices.

VI. Conclusion

The material selection for inductor coils plays a crucial role in determining their performance. By understanding the properties of different materials and how they impact the coil’s performance, it is possible to optimize the design and construction. Introduction As an electrical engineer, I’ve always been fascinated by the intricate workings of inductor coils. These seemingly simple components play a crucial role in many electrical applications. Their performance can significantly affect the efficiency and effectiveness of the devices they are part of. One of the key factors that determine the performance of an inductor coil is the material from which it is made.

ZXcompo is a manufacturing company specializing in custom inductors, capacitors, resistors, and more. Find high-quality passive electronic components for your projects. If you have product needs and inquiries. Please contact us now: sales@ZXcompo.com