Wirewound inductors are suitable for power supply circuits and are widely used in micro TVs, LCD TVs, cameras, etc. The basic functions of chip wound inductors: filtering, oscillation, delay, trapping, etc.; figuratively speaking: “pass DC and block AC”.

Detailed explanation: In electronic circuits, inductors are used to limit AC current. They can form high-pass or low-pass filters, phase-shifting circuits, and resonant circuits with resistors or capacitors. Transformers can perform AC coupling, voltage conversion, current conversion, and impedance conversion.

(★ If you want to know more information, you can refer to the following article: •The Difference Between Shielded Inductors and Unshielded Inductors | Zxcompo Inductor Factory)

The role of the chip wound inductor seems somewhat contradictory. We have said that the capacitor passes AC and blocks DC, while the inductor is just the opposite; its role is to pass DC and block AC. Originally, the direction and size of the magnetic field generated by the DC passing through the inductor are consistent and will not change.

When the alternating current changes from positive to negative, the magnetic field will also change. Since the time from positive (negative) to negative (positive) is very short, assuming that the potential is positive first and continues to rise, the magnetic field around the inductor will continue to increase and reach a maximum value at the top. At this time, the potential begins to drop. Due to the existence of the surrounding magnetic field, the inductor will convert the surrounding magnetic field into electrical energy and maintain the electrical energy for a while, and vice versa, thereby preventing the passage of alternating current.

What factors are related to winding inductance? The answer is that winding inductance is influenced by the magnetic core and the wire. The magnetic core and the wire are the two primary materials that comprise the winding inductor, significantly affecting the fundamental performance of the inductor.

The Influence of Magnetic Core on Winding Inductance:

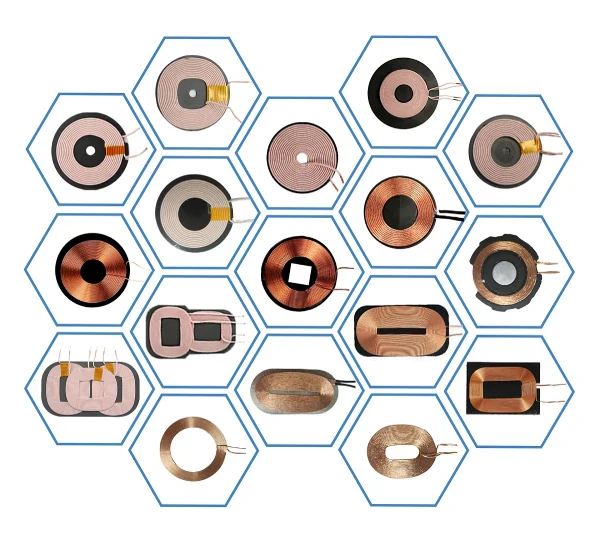

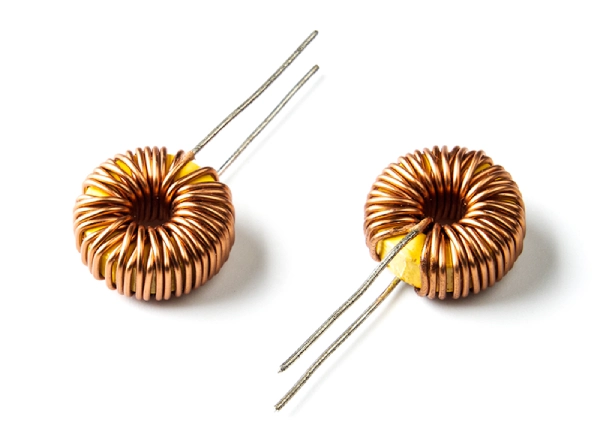

I-shaped inductors, R-type inductors, magnetic ring inductors and most chip power inductors are typical winding inductors. What they have in common is that the magnetic core is wound with enameled wire. The influence of magnetic core on winding inductance includes inductance, DC resistance (DCR), rated current, etc. This influence is related to the material, specification and size of the magnetic core.

1. The Influence of Core Material on Winding Inductance

Different core materials have different magnetic fluxes. When other factors remain unchanged, replacing the core with the same shape and specification but different materials will affect the inductance of the winding inductor.

According to the inductance calculation formula of the winding inductor L = (k*μ0*μs*N*N*S)/l, the greater the magnetic permeability μs of the core material, the greater the inductance of the winding inductor.

2. The Influence of Core Size on Winding Inductance

We know that the inductance of a coil with a core is greater than that of an air-core coil. The core has a greater influence on the inductance of a winding inductor. Generally speaking, when the number of turns of the winding inductor remains unchanged, we can know from another inductance calculation formula, L=μ×S*(N*N)/l, that the thicker the core (the larger the core diameter), the greater the inductance.

When other parameters remain unchanged, the core diameter increases, the inductance value decreases, the DC resistance (DCR) increases, and the DC superposition capacitance also increases. This is because the copper wire cuts off the magnetic flux, making the magnetic circuit longer and the total magnetic resistance increasing. L=N^2/R, R increases, L decreases. In addition, the core size will also affect the package size of the winding inductor. The larger the core size, the larger the package size of the inductor.

3. The Magnetic Core Affects the use Range of Winding Inductance

The scope of use of winding inductors made of different magnetic cores is different due to the limitations of the core material performance. For example, the DC resistance (DCR) of ferrite core winding inductors is large and the Curie temperature is high. They can be used as power inductors, chokes and energy storage inductors. The electromagnetic compatibility (EMC) characteristics of iron powder core winding inductors are strong, and they are more suitable for use as filters to reduce electromagnetic interference.

Advantages of Zxcompo Inductors

Zxcompo products include multilayer power inductors, wound surface mount inductors, and molded surface mount inductors for power and signal lines. A full range of passive electronic and magnetic components including inductors, capacitors, resistors, transformers, and filters are available. Our products are widely used in automotive, telecommunications, consumer electronics, and other fields. Each product is designed to achieve performance and maximize signal and power efficiency while saving space.

Other Advantages Include:

Fully automated manufacturing

High-reliability AEC-Q200

ISO 9001 quality standards

RoHS compliant

REACH compliant

Why Choose Zxcompo?

Our company has more than 1,000 types of inductors and 15 years of experience in this field. It is a product that produces extremely low resistance over a wide frequency range. Zxcompo is widely recognized by a global technical team for designing, manufacturing, and providing high-quality, high-performance signal integrity and noise filtering solutions.

Zxcompo brand inductors, also known as coils or reactors, are passive electronic components that resist changes in the current flowing through them. Core material, winding type and geometry play a critical role in the performance of power inductors. Shipping worldwide. Simply contact us for samples: sales@ZXcompo.com.